wollongongrestumping@gmail.com

Steel vs Concrete Stumps: Which Is Best for Coastal Homes?

Restumping decisions for coastal homes involve unique considerations beyond those affecting inland properties. The corrosive salt-laden environment, shifting sandy soils, and elevated moisture levels characteristic of coastal areas dramatically affect foundation longevity and performance. Wollongong homeowners choosing between steel and concrete stumps must evaluate how each material withstands these harsh conditions over decades of service. Understanding the strengths, vulnerabilities, and long-term costs associated with steel versus concrete stumps in coastal environments helps you make informed decisions that protect your property investment while balancing initial costs against lifecycle expenses.

Understanding Coastal Foundation Challenges

Coastal properties face environmental stresses that accelerate foundation deterioration compared to inland homes. These unique challenges fundamentally affect how different stump materials perform and which options provide optimal value in seaside locations.

Salt exposure creates corrosive conditions affecting all metal components. Ocean spray and salt-laden winds deposit sodium chloride on foundations, where moisture maintains the salt in dissolved form that actively corrodes steel. This corrosion progresses continuously in coastal environments, unlike inland areas, where steel corrosion primarily occurs during wet periods. The constant presence of salt accelerates corrosion rates five to ten times compared to non-coastal locations, dramatically reducing steel stump lifespan when protective measures prove inadequate.

Sandy soils common in coastal areas create different foundation dynamics than clay soils inland. Sand provides excellent drainage, preventing water accumulation around stumps, which benefits both steel and concrete by reducing sustained moisture exposure. However, sandy soils also shift more readily than clay, creating lateral forces and settlement patterns that foundations must accommodate. These soil movements stress stump connections to bearers and can create uneven settlement if stumps are not properly sized and positioned for load distribution.

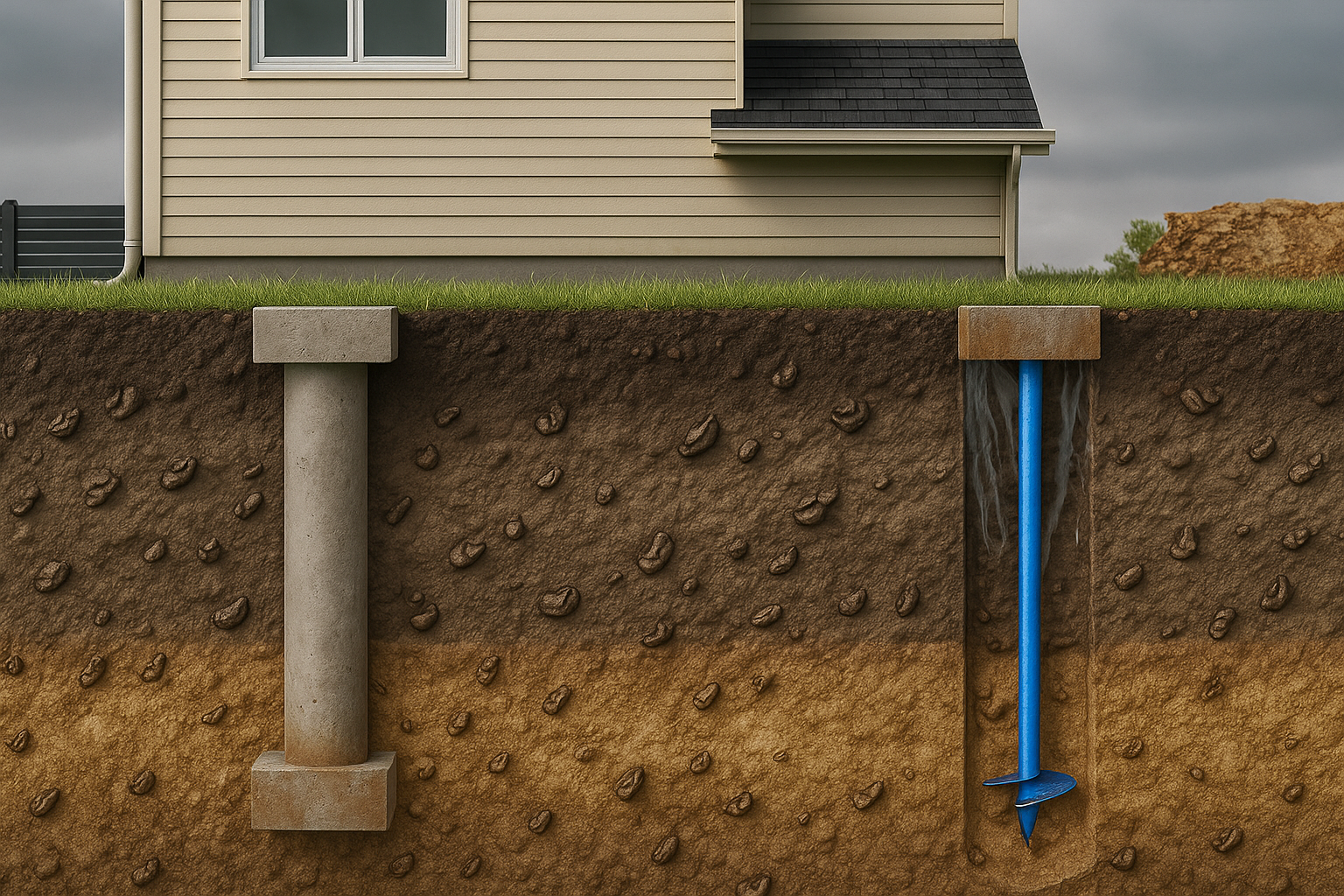

Elevated water tables in coastal areas affect the below-ground portions of stumps. Many coastal properties have water tables within one to two metres of surface level, meaning lower stump sections remain perpetually submerged or in saturated soil. This continuous water contact accelerates the deterioration of both steel and concrete through different mechanisms. Steel suffers enhanced corrosion, while concrete experiences potential chemical attack from salts dissolved in groundwater. Understanding where water tables intersect your stumps guides material selection and protective treatment requirements.

Termite activity remains significant despite coastal locations. Many people mistakenly believe salt environments deter termites, but these pests remain active in coastal areas and readily attack timber components of houses, even when salt-treated stumps are used. This termite pressure affects foundation choices, as termite-proof materials like steel and concrete provide advantages over traditional timber stumps regardless of preservative treatments. The combination of termite risk and corrosion challenges makes coastal restumping particularly complex.

Wind loads from coastal weather events create dynamic stresses. Coastal homes experience stronger, sustained winds and severe storm events more frequently than inland properties. These wind loads create lateral forces on stumps that must transfer safely into soil without movement or failure. Stump selection must account for these wind loads, ensuring adequate strength and proper bracing to maintain structural stability during severe weather. The engineering requirements for coastal homes often exceed the minimum standards developed for average conditions.

Steel Stump Characteristics in Coastal Environments

Steel stumps offer specific advantages and face particular challenges in coastal applications. Understanding how galvanised steel performs in salt environments helps you evaluate whether steel represents the best choice for your coastal property.

Galvanised coatings protect steel from corrosion. Hot-dip galvanising applies zinc layers to steel surfaces, creating barriers between steel and the corrosive environment. The zinc coating sacrifices itself through preferential corrosion, protecting the underlying steel as long as zinc remains. Quality galvanising for coastal applications should meet AS/NZS 4680 specifications with a minimum coating thickness of 85 microns. This protective layer significantly extends steel life in corrosive environments compared to unprotected steel, though it does not provide indefinite protection.

Coating degradation occurs progressively in salt environments. Even quality galvanising deteriorates faster in coastal conditions than inland, with zinc consumption rates potentially doubling or tripling near the ocean. Galvanised coatings might last 40 to 60 years inland but only 15 to 25 years in harsh coastal exposures before zinc depletes and steel corrosion begins. Understanding this accelerated deterioration helps set realistic expectations about steel stump longevity in your specific coastal location. Properties within 500 metres of the ocean experience the harshest conditions.

Additional protective measures extend the steel stump's life. Beyond galvanising, protective paints, powder coatings, or epoxy systems can be applied to galvanised steel, creating multiple barrier layers. These supplementary coatings require periodic inspection and maintenance to remain effective. Some coastal installations use stainless steel stumps in the most aggressive exposures, though costs increase substantially. Plastic sleeves protecting above-ground stump sections from direct salt spray offer another protective option worth considering for harsh locations.

Structural advantages include high strength-to-weight ratios. Steel stumps achieve required load capacities with relatively small cross-sections compared to concrete. This compactness allows installation in restricted access areas where concrete stumps would be difficult to position. Steel stumps also provide consistent manufactured quality, eliminating the variability sometimes present in poured concrete. The ductility of steel allows some deformation under extreme loads without catastrophic failure, providing a warning before collapse.

Installation efficiency suits many projects. Steel stumps arrive at job sites ready to install, requiring no curing time. Installation progresses rapidly compared to concrete alternatives involving formwork, pouring, and waiting for strength development. This speed reduces labour costs and project duration, making steel attractive for many restumping projects. Mobile hydraulic equipment can position steel stumps efficiently, even in challenging terrain common in coastal areas.

Installation Process Differences

The practical aspects of how steel versus concrete stumps are installed affect project timelines, site disruption, and suitability for different property configurations. Understanding installation differences helps you anticipate project logistics.

Steel stump installation speed provides schedule advantages. Pre-manufactured steel stumps arrive ready to install, requiring only positioning, levelling, and connection to the house frame. A typical house restumping with steel might be completed in 3 to 5 days, including site preparation and finishing work. This rapid installation minimises the time your house remains on temporary supports and reduces the period during which you cannot fully occupy your home. For projects where the timeline matters significantly, steel's installation speed provides real value.

Concrete stump installation methods vary. Precast concrete stumps are installed similarly to steel, arriving manufactured and requiring only positioning. Cast-in-place concrete involves building formwork, placing reinforcement, pouring concrete, and allowing adequate curing before loading. Pre-cast stumps install in 4 to 6 days, similar to steel, while cast-in-place work requires 7 to 10 days, including curing time. The installation method affects both schedule and cost, with cast-in-place generally costing less for materials but requiring more labour time.

Site access requirements differ slightly. Steel stumps' lighter weight allows manual handling in very restricted areas where machinery cannot access. Concrete stumps require mechanical lifting equipment for positioning, limiting installation in extremely tight spaces. However, most residential properties provide adequate access for either material. In the rare situations where access is severely restricted, steel's handling advantages become significant and may determine material selection despite other considerations.

Excavation requirements are similar for both materials. Both steel and concrete stumps require excavation to an appropriate depth determined by soil conditions and design requirements. In coastal sandy soils, stumps typically extend 600mm to 1200mm below ground, deeper than inland clay soil installations. The excavation work represents a similar effort regardless of stump material choice. Sandy soil's ease of digging partially offsets the deeper excavation requirements common in coastal applications.

Underpinning existing stumps during installation affects occupied homes. When restumping while homeowners remain in residence, the house must be temporarily supported while old stumps are removed and new ones installed. This underpinning process is similar for steel or concrete installations and represents the primary source of disruption and risk during restumping. Both materials allow sequential stump replacement that maintains structural support throughout the project, making material choice relatively neutral regarding occupied installation feasibility.

Making the Decision for Your Coastal Property

Synthesising all considerations into a decision appropriate for your specific circumstances requires weighing multiple factors and priorities. No single answer suits all coastal homes, but systematic evaluation leads to optimal choices for individual situations.

Properties within direct salt spray zones favour concrete. Homes within 200 to 500 metres of the ocean face maximum corrosion exposure, where even quality galvanised steel struggles to achieve acceptable longevity. In these harshest locations, concrete's corrosion immunity provides a compelling advantage justifying any cost premium. The combination of salt spray, wind-driven moisture, and elevated airborne chlorides creates conditions where steel protection systems degrade rapidly. Unless you are committed to intensive maintenance and accept a shorter service life, concrete represents the prudent choice for most direct coastal exposures.

Budget-constrained projects may choose steel with planned replacement. If initial cost constraints dominate decision-making and you accept that steel stumps will require replacement sooner, steel remains a viable option. This choice makes sense when you plan relatively short property ownership or when budget limitations make concrete unaffordable. However, understand that you are choosing a lower initial cost over longer-term value. This can be a rational decision for rental properties, vacation homes, or situations where minimising immediate expense outweighs lifecycle considerations.

Long-term owners prioritising low maintenance favour concrete. Homeowners planning decades of property ownership benefit most from concrete's durability and minimal maintenance requirements. The higher initial investment is distributed over many years of service, reducing annualised costs below steel alternatives requiring periodic recoating and earlier replacement. Peace of mind from knowing foundations will outlast your ownership period has value beyond simple economic calculation. For forever homes in coastal locations, concrete stumps represent logical choices aligning with long-term ownership plans.

Engineered solutions may combine materials strategically. Some restumping projects use concrete stumps in most exposed locations while using steel stumps in more sheltered areas under the house centre. This hybrid approach optimises material selection for different exposure zones. Stumps receiving direct weather exposure or nearest to the ocean use corrosion-immune concrete, while protected internal stumps use more economical steel. This engineered approach requires professional design but can optimise both performance and cost.

Professional assessment provides site-specific guidance. Rather than making material decisions in isolation, engage structural engineers or experienced restumping contractors for site-specific recommendations. These professionals assess your property's exposure, soil conditions, structural requirements, and budget to recommend optimal solutions. Their experience with local coastal conditions guides material selection in ways general guidance cannot match. The cost of professional assessment, typically $500 to $1,500, provides valuable decision support for foundation investments worth $6,000 to $12,000 or more.

Installation Quality and Contractor Selection

Regardless of material choice, installation quality critically affects foundation performance and longevity. Understanding what constitutes proper installation and how to select qualified contractors ensures your investment delivers intended value.

Licensed and insured contractors, like Wollongong Restumping, provide essential protections. Verify that restumping contractors hold appropriate licences for structural work and carry adequate insurance, including public liability and workers' compensation. Licensed contractors demonstrate minimum competency and provide accountability through licensing bodies if problems arise. Insurance protects you from liability if workers are injured on your property or if defects cause damage. Never use unlicensed operators regardless of cost savings, as risks far outweigh any financial benefits.

Experience with coastal installations specifically matters. Restumping coastal homes requires understanding salt environment challenges and appropriate protective measures. Ask contractors about their coastal project experience and request references from previous coastal clients. Contractors primarily working inland may lack familiarity with marine environment requirements. Specific experience with coastal projects in the Wollongong area provides the most relevant expertise.

Quality material specifications should be documented. Request written specifications confirming galvanising standards for steel stumps or concrete mix design for concrete options. Vague commitments to "quality materials" lack accountability. Documented specifications allow verification that supplied materials meet agreed standards. For coastal projects, this documentation might include galvanising thickness certifications or concrete test results confirming appropriate strength and durability characteristics.

Installation process observation identifies quality issues. If practical, observe key installation stages, including excavation depth, footing preparation, stump positioning, and connection work. Many problems result from cutting corners during installation that may not be visible after work is completed. While you likely lack the technical expertise to judge all aspects, general care and attention to detail are apparent. Do not hesitate to question practices that appear rushed or careless.

Warranties should cover both materials and workmanship. Responsible contractors offer warranties spanning 5 to 10 years covering defects in materials and installation. These warranties provide recourse if problems emerge from substandard work. Review warranty terms carefully, understanding what is and is not covered. Warranties that exclude almost everything or impose unreasonable maintenance requirements offer little real protection. Strong warranties from stable businesses provide valuable long-term assurance.

Conclusion

Choosing between steel and concrete stumps for Wollongong coastal homes requires balancing multiple factors, including corrosion resistance, longevity, costs, and site-specific conditions. Concrete stumps provide superior performance in harsh coastal environments through fundamental immunity to salt corrosion, with properly manufactured concrete stumps lasting 50 to 80 years compared to 25 to 40 years for even well-maintained steel in direct coastal exposures. While steel stumps offer lower initial costs, typically $1,000 to $2,000 less than concrete for complete house restumping, lifecycle costs often favor concrete when maintenance requirements and earlier replacement needs are factored into long-term economic analysis. The corrosive salt-laden conditions within 500 meters of the Wollongong coastline create particularly challenging environments where concrete's advantages become most compelling.

For homeowners planning long-term property ownership, prioritizing low maintenance, and accepting higher upfront investment for superior longevity, concrete stumps represent optimal choices for coastal applications. Steel stumps remain viable for budget-constrained projects, properties in less exposed coastal locations beyond direct salt spray zones, or situations where shorter-term solutions align with ownership plans and financial constraints. The decision ultimately depends on your specific property location, budget parameters, ownership timeline, and maintenance willingness. Regardless of material choice, using licensed experienced contractors familiar with coastal installation requirements and specifying appropriate protective measures ensures your foundation investment delivers maximum value and protects your coastal home throughout decades of service in demanding marine environments.

About Wollongong Restumping

Wollongong Restumping specializes in foundation solutions for coastal properties throughout the Wollongong region, with deep experience addressing the unique challenges salt environments create for house stumps. Their team provides a comprehensive assessment of existing foundations, professional recommendations on steel versus concrete stump selection based on site-specific exposure and conditions, and expert installation using materials and techniques optimized for coastal durability. They source quality hot-dip galvanized steel stumps meeting AS/NZS 4680 specifications and concrete stumps manufactured to coastal exposure standards with appropriate cover over reinforcement and low permeability mixes. Wollongong Restumping maintains full licensing and insurance for structural work and offers transparent written quotes itemizing materials, specifications, and installation procedures. Their warranty coverage spans materials and workmanship, providing long-term assurance for foundation investments. With decades of combined experience restumping coastal homes from Port Kembla to Kiama, Wollongong Restumping understands how different foundation materials perform in local marine conditions and guides homeowners toward decisions balancing performance requirements with budget realities.

Ready to work with Wollongong Restumping?

Let's connect! We’re here to help.

Send us a message and we’ll be in touch.

Or give us a call today at 0242026325